From mechanical saws to abrasive water jet cutting claxton has the cutting solutions to cut through the toughest materials in the harshest environments.

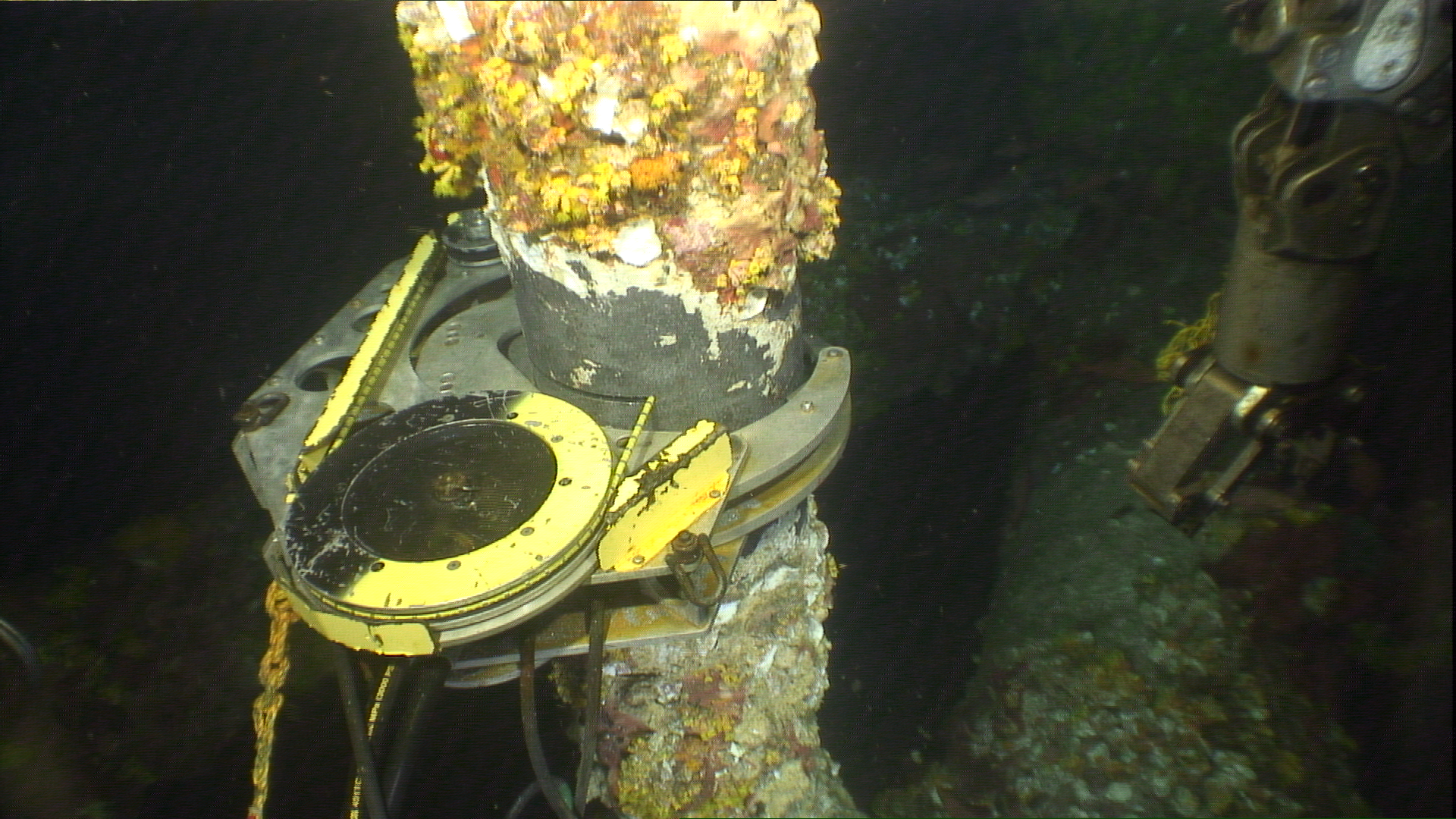

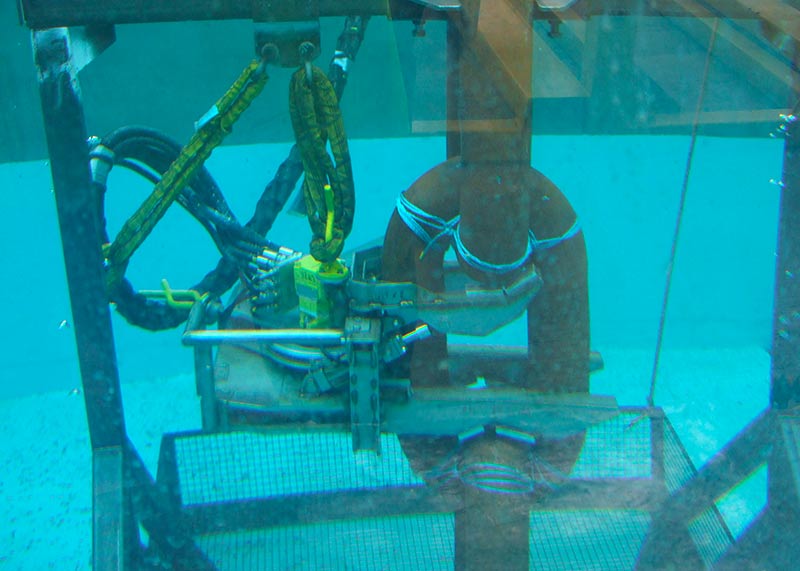

Diamond wire cutting underwater.

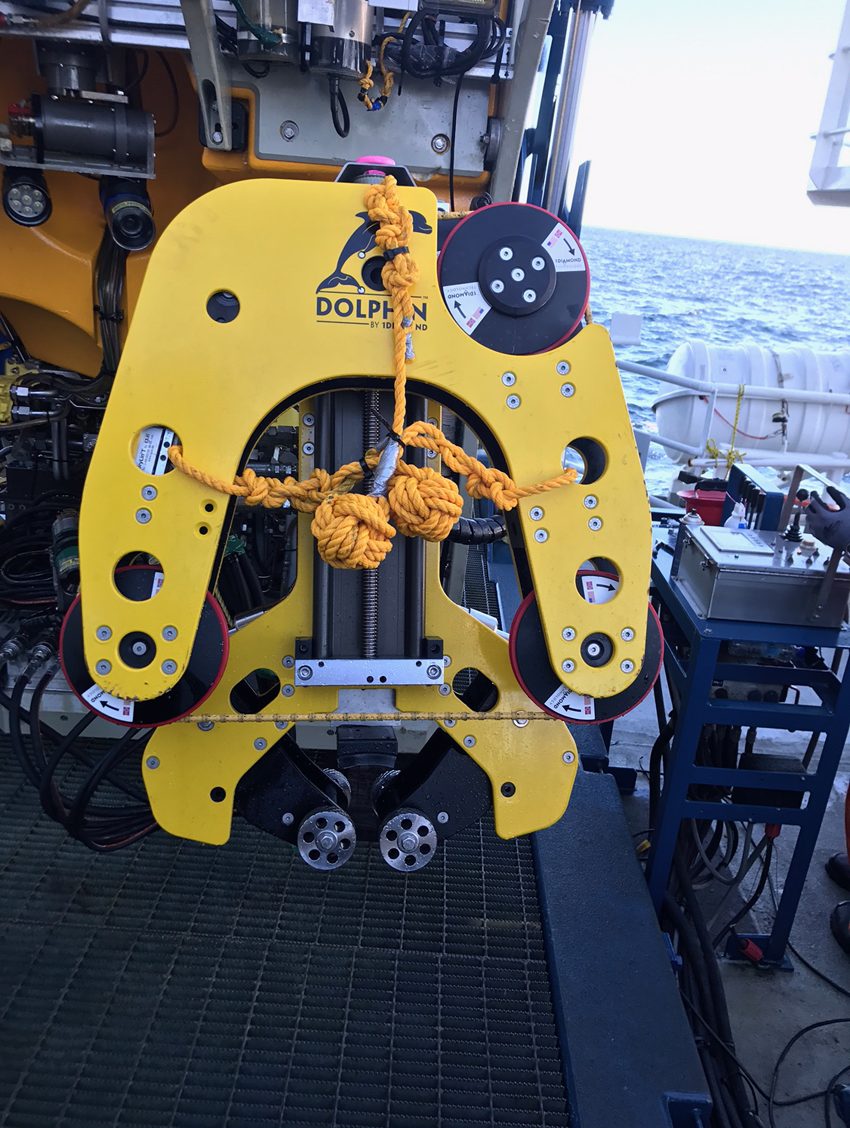

Cut provide off the shelf and bespoke engineered diamond wire cutting solutions for clients operating in the oil and gas nuclear renewable and decommissioning sectors.

0 projects completed.

The pioneer of diamond wire sawing.

Cutting underwater technologies cut has more than 25 years experience in providing both off the shelf and bespoke diamond wire cutting solutions globally.

Underwater cutting solutions prides itself on the quality and reliability of the service it provides to its clients underpinned by the recognition of various professional associations and industry standards.

A specialty diamond wire cutting and concrete core drilling contractor we provide tailored field services for land based and underwater concrete and metal cutting applications.

While the machine can be used topside it is not considered a cold cutting method when used for surface operations.

From our bases in aberdeen and singapore and brazil the cut group has successfully performed more than 6500 cuts.

With their small footprint and remote operation our diamond wire saws excel at underwater concrete cutting and at cutting on confined space and limited access jobsites.

Since every job is unique the umx team designs coordinated visual plans to boost efficiency and clarity on the jobsite.

Thirty six years ago bluegrass became the first demolition company to use diamond wire saws for controlled demolition since then our saws have been used in all major industries to cut an array of materials and objects but primarily concrete and metal structures.

Perform efficient topside and underwater cutting on caissons jackets pipes piles multi string casings and wellheads with claxton s diamond wire cutting machines.

Mirage diamond wire saws are ideal for quickly cutting through dissimilar materials and resisting compressive forces.