The extra sharp cutting power of ceramic grain combined with reinforced fibers throughout this wheel swiftly meet the challenge of cutting into or removing metal.

Difference between ceramic and ceramic grain cut off wheel.

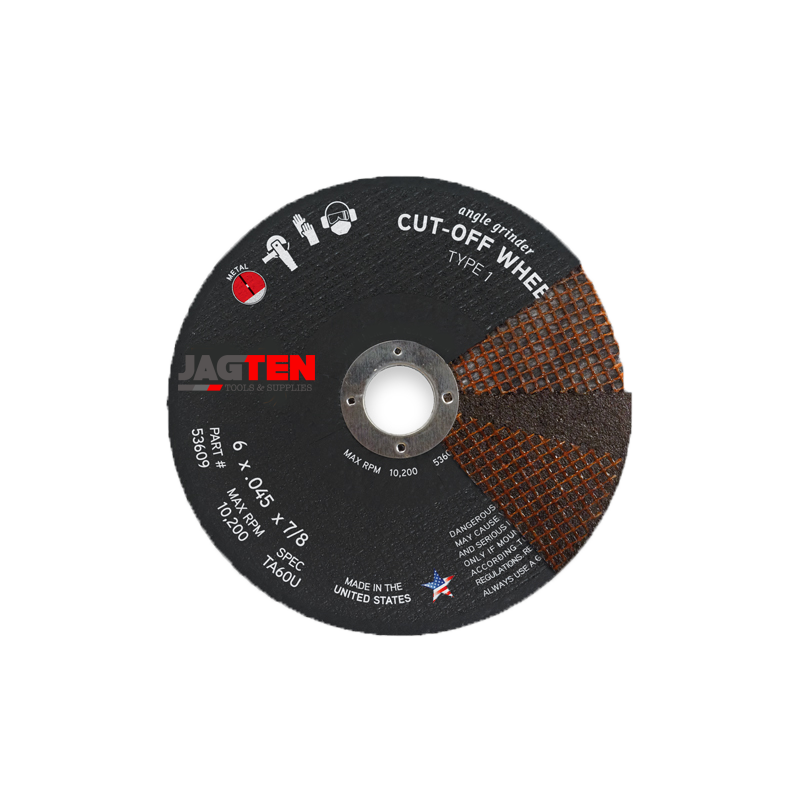

Used primarily on metal applications.

Ceramic grain grinding and cut off wheels.

Grinding wheels remove material from metal glass wood brick or concrete.

They are the newest grain innovation and represent the ultimate in performance providing an aggressive consistent cut under moderate to high pressure.

Ceramics also tend to cut cooler minimizing discoloration while maximizing product life.

Grinding wheels remove material from metal glass wood brick or concrete.

Ceramic cutting wheels allow for a very long life and fast cutting speeds.

These wheels are not to be used for grinding.

Metal cutting wheels contain either zirconia or aluminum oxide depending on their intended use.

Within the united abrasive product line the saitech and the ultimate ceramic cutting wheels both feature ceramic grain technology.

This ultimately reduces the regularity that the grinding wheel needs dressing as well and providing a significantly cooler cutting action when in use.

This wheel offers precision performance on carbon steel as well as stainless steel.

Use for cut off applications o.

Grinding wheels and cut off wheels are covered in abrasive grit and used for grinding cutting and machining applications.

Wheels are used with power tools and industrial machines such as angle grinders or bench grinders.

Cut off wheels cut or notch these surfaces.

Grinding wheels and cut off wheels are covered in abrasive grit and used for grinding cutting and machining applications.

Cut off wheels cut or notch these surfaces.

Ceramic aluminum oxide and zirconia alumina blend for stainless and carbon steels other ferrous and exotic metals.

Harder than standard aluminium oxide with a very sharp abrasive grain.

Hallen says silicon carbide is the hardest of the three types and aluminum oxide is the softest.

This ceramic grain has a unique microcrystalline structure that is self sharpening.

The distinction becomes important as a wheel is used and abrasive particles fracture to expose fresh cutting surfaces.

Approach the toughest high speed cutting tasks with this high performing standard abrasives ceramic cut off wheel.

3m cubitron ii cut off wheel 3m cubitron ii cut off wheel features 3m precision shaped ceramic grain to bring you an exceptionally fast cutting and long lasting wheel for use on almost all materials including stainless.

Description contains premium ceramic grain extremely long life and fast cut rate lowest cost per cut of any cut off wheel coolest cleanest and fastest grain available made in usa works well on all metal working applications exceptional results on stainless steel and aluminum note.